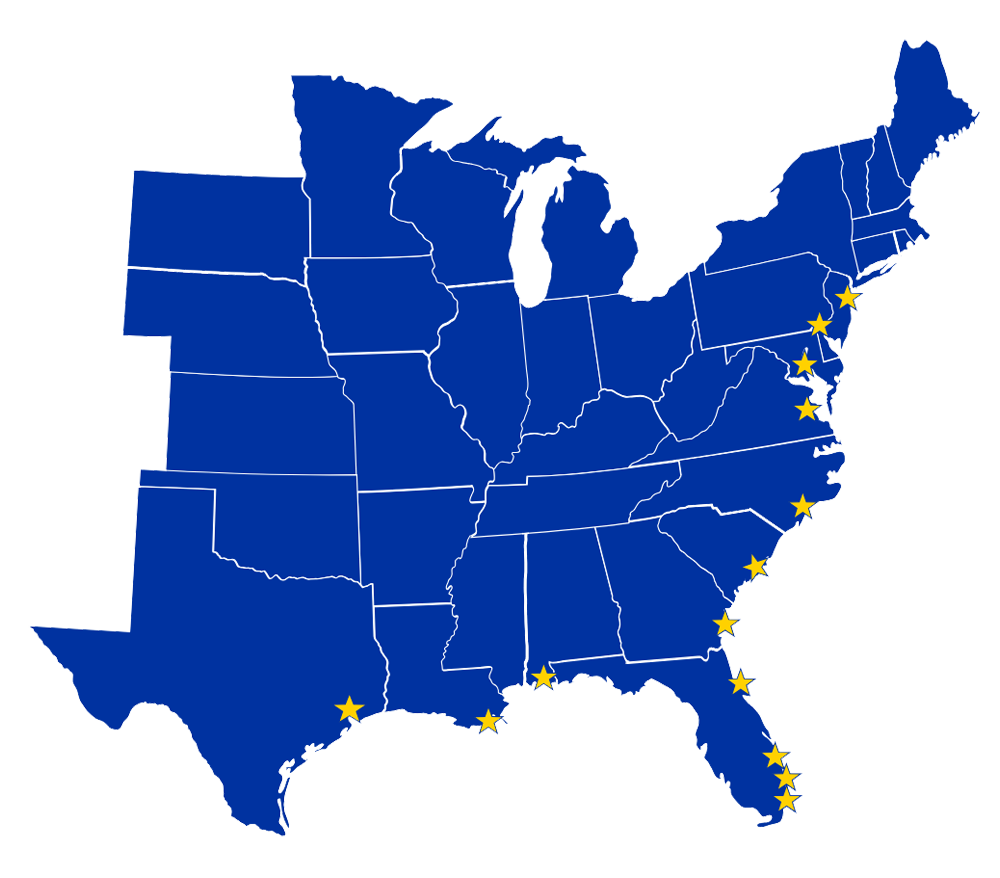

As widely reported, if workers at East and Gulf Coast ports strike on Oct. 1, manufacturing supply chains throughout the U.S. will be severely impacted. The National Association of Manufacturers (NAM) published a very insightful, interactive map of the ports that will be potentially impacted and some interesting import/export facts for many of them. Check it out here:

As widely reported, if workers at East and Gulf Coast ports strike on Oct. 1, manufacturing supply chains throughout the U.S. will be severely impacted. The National Association of Manufacturers (NAM) published a very insightful, interactive map of the ports that will be potentially impacted and some interesting import/export facts for many of them. Check it out here:

https://nam.org/mapping-the-impact-of-a-port-strike-32072

According to NAM, here some key data points:

- More than 68% of all containerized exports and more than 56% of containerized imports flow through East and Gulf Coast ports, representing an average daily trade value of more than $2.1 billion.

- They handle more than 91% of containerized imports and 69% of containerized exports of pharmaceutical products.

- They also process more than 76% of containerized vehicle exports and more than 54% of containerized vehicle imports.

- For air and spacecraft, more than 77% of containerized exports and more than 51% of containerized imports go through these ports.

To prepare for a potential labor strike by the International Longshoremen’s Association (ILA) on the Gulf Coast and East Coast, importers and exporters can consider several contingency plans:

- Reroute Cargo: Explore alternative shipping routes. Ports on the U.S. West Coast, Canada, and Mexico can serve as viable alternatives. For example, cargo can be diverted to ports like Los Angeles, Long Beach, or Vancouver.

- Multi-Coastal Transportation Network: Establish a network that includes multiple coastal gateways. This can involve setting up transload operations or smaller volume operations that can be scaled up if needed.

- Extended Gate Hours: Take advantage of ports extending their gate hours to process as much cargo as possible before any potential strike. Ports like New York, New Jersey, and Savannah are offering extended weekend hours.

- Airfreight Options: For time-sensitive shipments, consider using airfreight, although it comes at a higher cost and with capacity concerns.

- Communication with Ports and Carriers: Stay in close contact with ports and carriers for the latest updates and advisories. Many ports are sharing daily updates about their contingency plans.

- Inventory Management: Increase inventory levels of critical goods to buffer against potential delays. This is especially important for industries relying on just-in-time inventory models.

- Legal and Contractual Preparations: Review contracts and legal agreements to understand the implications of delays and disruptions. Ensure there are clauses that cover force majeure events like strikes.

Working with an experienced capable freight forwarder, like Logistics Plus, importers and exporters can implement the above strategies and better navigate the potential disruptions caused by a labor strike.