by logisticsplus | Feb 22, 2021 | News

After years of negotiation and uncertainty, we are officially in the post-Brexit era. To preserve their mutually beneficial trading relationship, the European Union (EU) and United Kingdom (UK) reached a deal that went into place on January 1, 2021. While the agreement is beneficial for both parties, questions remain about its impact on the logistics and transportation industry. The new regulations at the border are already causing major blocks and delays.

After years of negotiation and uncertainty, we are officially in the post-Brexit era. To preserve their mutually beneficial trading relationship, the European Union (EU) and United Kingdom (UK) reached a deal that went into place on January 1, 2021. While the agreement is beneficial for both parties, questions remain about its impact on the logistics and transportation industry. The new regulations at the border are already causing major blocks and delays.

Here are some things that logistics and supply chain companies must take into account after the newest regulations:

- Traders must consider the rules of origin. These complex rules apply to goods that qualify for preferential trade terms under the agreement.

- All imports and exports are subject to customs formalities. Trading in both the UK and EU means complying with two different tax and legal systems.

- Companies are facing higher logistics costs. Trucking companies are reluctant to cross the border resulting in less capacity and higher surcharges.

- All imports into the EU must meet new standards and will be subject to regulatory checks and controls for safety, health, and other public policy purposes.

- Traders are obliged to change their delivery terms with their suppliers and customers from DDP to DAP to avoid complex customs procedures.

- Some traders face cash flow issues as import Value Added Tax (VAT) is payable when entering the European Union.

As a result of the new regulations, the Logistics Plus Europe team has noticed that many traders are not fully prepared for this transition. Increased potential for delays means that you need to have tight control over every aspect of your supply chain. Once you have full visibility of your supply chain, you can begin to plan and break down how the post-Brexit era changes things on an operational level.

At Logistics Plus, we understand the impact of these new regulations and how they affect customers and their transport flows. Our European team operates distribution centers in the UK and in the Netherlands that offer full customs brokerage services and regular trucking transfers between the two countries. We have a wide variety of services to help our customers optimize and facilitate European and UK VAT requirements. Additionally, Logistics Plus offers Importer of Record (IOR) and Exporter of Record (EOR) services that our customers can count on for a non-disrupted supply chain.

If you need assistance navigating the post-Brexit logistics era, please contact our team of logistics experts today.

by logisticsplus | Feb 18, 2021 | News

Yesterday we announced that Logistics Plus is being profiled in the Inbound Logistics 2021 Logistics Planner. The profile and accompanying advertisement introduced our newest descriptor … A 21st Century Logistics Company ™. So what does it mean to be a 21st-century logistics company? First and foremost, it means that Logistics Plus is a reliable partner known for developing creative solutions to critical challenges. It also means that Logistics Plus, over the past 25 years, has developed key traits to address contemporary supply chain opportunities and problems. As it pertains to you and your business, that means:

Yesterday we announced that Logistics Plus is being profiled in the Inbound Logistics 2021 Logistics Planner. The profile and accompanying advertisement introduced our newest descriptor … A 21st Century Logistics Company ™. So what does it mean to be a 21st-century logistics company? First and foremost, it means that Logistics Plus is a reliable partner known for developing creative solutions to critical challenges. It also means that Logistics Plus, over the past 25 years, has developed key traits to address contemporary supply chain opportunities and problems. As it pertains to you and your business, that means:

- We manage your logistics so you can focus on your core business.

- We have been in business for nearly 25 years, and our teams have a wide variety of skills across many disciplines – we can do pretty much anything needed across your entire supply chain.

- Our teams can integrate with your company in various ways, from full-time onsite resources to offsite logistics management of multiple locations.

- We manage inbound and outbound domestic freight and international cargo.

- Using technology, business intelligence, and global supply chain control towers, we can connect all the links in your supply chain, from vendors to end customers.

- Our services are customized to your needs, so you always get exactly what you want and need.

- We have offices in close to 30 countries throughout the world, and we have valued partners in dozens of others.

- Our professionals keep up with the constantly changing logistical landscape – after all, this is still very much a people business.

- We are big enough to be effective but small enough that your business will be important to us – we call this the ‘Goldilocks Zone.’

- With a Passion For Excellence™, we are the company that is focused on solving problems and taking away your headaches!

If you haven’t already, we invite you to watch our introductory video below. As we explain in the video: Logistics is in our DNA … this is what we do. Let us do it for you too!

What’s your logistics or supply chain challenge? Contact us for a 21st-century solution today.

by logisticsplus | Feb 17, 2021 | News

Logistics Plus has been profiled as a top third-party logistics (3PL) company by Inbound Logistics for its 2021 Logistics Planner. In its 29th year of publication, the recognized industry planner helps companies find the right technology solutions and transportation and logistics partners to drive supply chain efficiency. With both print and digital editions, the annual issue is updated with profiles of leaders in transportation, technology, logistics, and more who stand ready to help businesses face upcoming challenges to optimize their supply chains.

Logistics Plus has been profiled as a top third-party logistics (3PL) company by Inbound Logistics for its 2021 Logistics Planner. In its 29th year of publication, the recognized industry planner helps companies find the right technology solutions and transportation and logistics partners to drive supply chain efficiency. With both print and digital editions, the annual issue is updated with profiles of leaders in transportation, technology, logistics, and more who stand ready to help businesses face upcoming challenges to optimize their supply chains.

The Logistics Plus profile appears on page 350 of the publication, and an accompanying advertisement appears on page 195. The profile and advertisement formally introduce our new but appropriate descriptor, A 21st Century Logistics Company™, to recognize the unique and contemporary ways that Logistics Plus develops creative solutions for today’s most critical supply chain challenges.

Working as your 3PL, 3½PL, or 4PL partner, Logistics Plus is the company that handles supply chain challenges from start-to-finish by doing what other logistics companies can’t or won’t do. We’re small enough to be agile and responsive to your needs, yet large enough to have a network of solutions that span your entire supply chain.

You can view PDF versions of the Logistics Plus profile and advertisement by clicking the two images below.

You can view the entire 2021 Logistics Planner digital edition online here: https://resources.inboundlogistics.com/digital/issues/IL_Digital_January2021.pdf

by logisticsplus | Feb 15, 2021 | News

As widely reported by freight industry media outlets, such as Freightwaves, Logistics Management, Journal of Commerce, and others, general freight rates – including those for less-than-truckload (LTL) services – continue to rise. Most experts are predicting high, single-digit rate increases in 2021, along with higher diesel fuel prices. Renewed economic demand, increases in e-commerce shipping, the influx of container shipments at the ports, limited truck capacity (the top 25 LTL carriers comprise 90% of the LTL market), scarcity of qualified drivers, and COVID-19 outbreaks and restrictions are all driving truckers to raise rates – particularly for small- and mid-sized freight shippers.

As widely reported by freight industry media outlets, such as Freightwaves, Logistics Management, Journal of Commerce, and others, general freight rates – including those for less-than-truckload (LTL) services – continue to rise. Most experts are predicting high, single-digit rate increases in 2021, along with higher diesel fuel prices. Renewed economic demand, increases in e-commerce shipping, the influx of container shipments at the ports, limited truck capacity (the top 25 LTL carriers comprise 90% of the LTL market), scarcity of qualified drivers, and COVID-19 outbreaks and restrictions are all driving truckers to raise rates – particularly for small- and mid-sized freight shippers.

Logistics Plus is a top freight brokerage firm with substantial freight spend and contracts with many leading carriers. That allows us to pass on competitive rates to our customers who might not otherwise have the freight volumes or expertise to negotiate competitive rates on their own. Additionally, when our own “general pricing” contracts are not competitive enough or lack certain customizations for a specific shipper’s freight profile, we can also negotiate “client-specific pricing” contracts for our customers too.

To get started, Logistics Plus offers risk-free freight analyses to shippers curious to know if they can save additional money on their freight spend. All we need is a sample shipment file (ideally three months or greater in Excel format) with, at minimum, the following data:

- Origin Zip Code

- Destination Zip Code

- Shipment Weight (in pounds)

- Freight Class (or detailed commodity description so we can ascertain the correct freight classification)

- Handling Units and Packaging Type(s)

Additionally, the following optional information is also helpful if it is available:

- Shipment Dimensions (L”xW”xH”)

- Accessorial services provided

- Actual freight charges (freight, fuel, and accessorial fees)

- Actual LTL carrier used

Using the information above, Logistics Plus will run a detailed freight analysis to determine if existing Logistics Plus contracts and carriers will result in material savings. If the initial study demonstrates potential savings, the customer will be asked to complete a Logistics Plus Customer Setup Application (if not already done) to obtain a shipping account to begin realizing the savings.

If the initial analysis does not demonstrate potential savings, or if the customer has specific pricing requirements that cannot be met with existing Logistics Plus contracts and carriers, then – if the customer is willing and able to complete the following Letter of Authorization (LOA) and RFP Checklist – Logistics Plus will conduct a client-specific request for proposal (RFP) to obtain more competitive pricing on behalf of the customer. Note: Customer is not required to activate or use RFP pricing; however, the LOA is required to go through the process. After client-specific pricing is activated, the customer should complete a Logistics Plus Customer Setup Application (if not already done) to obtain a shipping account and begin realizing the savings.

Contact us if you’re ready to have Logistics Plus conduct a risk-free freight analysis on your behalf. We’re here to help!

by logisticsplus | Feb 15, 2021 | News

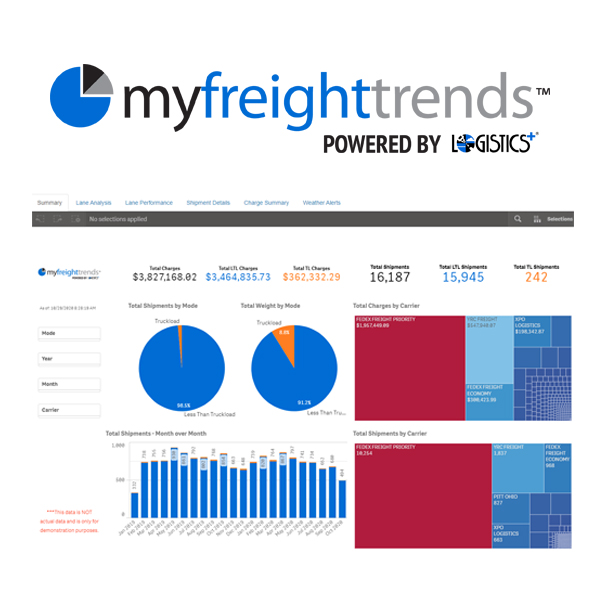

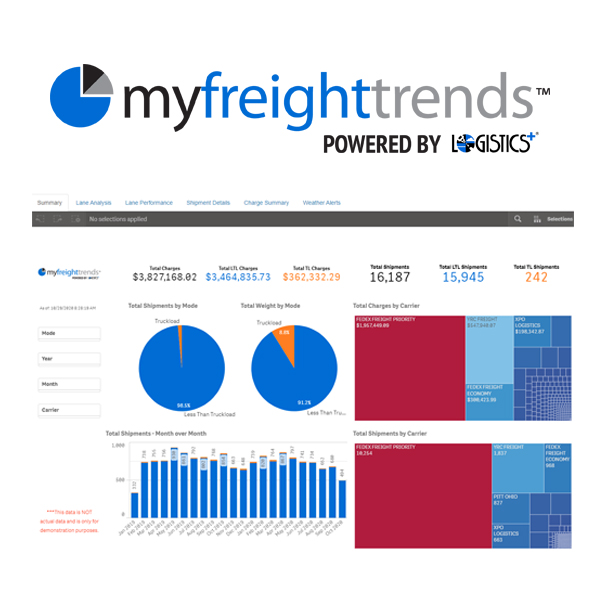

Logistics Plus is proud to announce that a new business intelligence tool called MyFreightTrends ™ has been embedded inside its cloud-based eShipPlus ™ transportation management system (TMS). The new tool is now universally available to all eShipPlus users. The off-the-shelf report provides customers with detailed dashboards and analytics regarding their North American freight shipping, including:

Logistics Plus is proud to announce that a new business intelligence tool called MyFreightTrends ™ has been embedded inside its cloud-based eShipPlus ™ transportation management system (TMS). The new tool is now universally available to all eShipPlus users. The off-the-shelf report provides customers with detailed dashboards and analytics regarding their North American freight shipping, including:

- A Summary report with total LTL and FTL spend by mode and by carrier;

- A detailed Lane Analysis report with network velocity metrics;

- A Lane Performance report with average shipment cost trends by location;

- A Shipment Details report that can be exported to Excel;

- A freight Charges Summary report with historical trending; and

- A Weather Alerts map detailing weather events that may impact domestic supply chains.

All the dashboard reports are highly interactive, meaning users can click on graphs and images to instantly filter views based on modes, carriers, lanes, and timeframe.

Watch the animated GIF below for a short preview.

Watch this 9-minute tutorial.

“Logistics Plus has been on the cutting-edge of business intelligence reporting the past few years, with highly customized reports for both our internal users and our larger 3PL and 4PL clients,” said Scott Frederick, vice president of marketing & LTL carrier relations for Logistics Plus. “With MyFreightTrends, we now have a very detailed and insightful off-the-shelf package we can make available to all of our customers, no matter how small or large.” Frederick added, “Of course, we can still provide additional report customizations for clients that need them as part of our overall business intelligence solution.”

Current users can log in to eShipPlus and view the MyFreightTrends dashboards under the reporting menu. Not a current eShipPlus user? Visit www.logisticsplus.com/tools/eshipplus/about/ to learn more.

by logisticsplus | Feb 12, 2021 | News

Global Trade Alert Message:

Global Trade Alert Message:

In one of Joe Biden’s first trade actions, he reinstated a 10 percent duty on aluminum imports from the United Arab Emirates (UAE). This tariff was previously in effect until former President Trump removed it just one day before leaving office. The United Arab Emirates is one of the world’s biggest aluminum producers. President Biden said, “In my view, the available evidence indicates that imports from the UAE may still displace domestic production, and thereby threaten to impair our national security.”

The full article can be found on Politico here: www.politico.com/biden-aluminum-tariff-uae

After years of negotiation and uncertainty, we are officially in the post-Brexit era. To preserve their mutually beneficial trading relationship, the European Union (EU) and United Kingdom (UK) reached a deal that went into place on January 1, 2021. While the agreement is beneficial for both parties, questions remain about its impact on the logistics and transportation industry. The new regulations at the border are already causing major blocks and delays.

After years of negotiation and uncertainty, we are officially in the post-Brexit era. To preserve their mutually beneficial trading relationship, the European Union (EU) and United Kingdom (UK) reached a deal that went into place on January 1, 2021. While the agreement is beneficial for both parties, questions remain about its impact on the logistics and transportation industry. The new regulations at the border are already causing major blocks and delays.

Logistics Plus is proud to announce that a new

Logistics Plus is proud to announce that a new