by logisticsplus | Feb 25, 2022 | News

Logistics Plus (LP) is pleased to announce that the Florida Department of Business & Professional Regulation (Florida DBPR) has granted a license to its Miami, Florida warehouse for the public storage of alcoholic beverages and spirits.

Logistics Plus (LP) is pleased to announce that the Florida Department of Business & Professional Regulation (Florida DBPR) has granted a license to its Miami, Florida warehouse for the public storage of alcoholic beverages and spirits.

Within the past year, a new company division, called LP Spirits™, has focused on growing the company’s alcohol and spirits warehousing and logistics needs. The Miami warehouse joins the Logistics Plus Chino, CA, Chicago, IL, and Erie, PA warehouses as locations that can legally store and distribute alcohol. The Logistics Plus Dayton, NJ warehouse is currently pending its license.

Logistics Plus Miami Branch Manager Oscar Cabrales is very excited about the opportunity this brings. “Alcohol and spirit warehousing and distribution can be quite tricky. I’m excited that we can join other Logistics Plus warehouses across the country by being able to offer this service. On top of warehousing the alcohol, we can provide valuable importation, compliance, and distribution solutions.”

Please contact miami@logisticsplus.com for additional information.

by logisticsplus | Feb 23, 2022 | News

Over a seven-week time frame, Logistics Plus employees Oleh Lykholat and Mykhailo Kostyshyn traveled around Europe to fix equipment and complete installs for a high-profile client. Nineteen flights, nine airports, six cars, two trains, and one metro later, Oleh and Mykhailo finished their journey. The story below, provided by Oleh, is a recap of their travels, jobs, and time spent working at various job sites in Europe.

Over a seven-week time frame, Logistics Plus employees Oleh Lykholat and Mykhailo Kostyshyn traveled around Europe to fix equipment and complete installs for a high-profile client. Nineteen flights, nine airports, six cars, two trains, and one metro later, Oleh and Mykhailo finished their journey. The story below, provided by Oleh, is a recap of their travels, jobs, and time spent working at various job sites in Europe.

Background Information

This was our first business trip with Logistics Plus. Our journey started on December 8th and finished on January 28th. We each had three brief home visits during that span. In total, we traveled and worked for fifty-two days and made it to four countries (Germany, Italy, Spain, and France). We were technically in Poland and Turkey as well, but only at the airports.

Traveling Across Europe

Generally, we had very few issues during our travels. The two of us are fully vaccinated, which made everything go pretty smoothly. Our closest situation was the Istanbul airport. Our flight from L’viv to Istanbul arrived fifty minutes later than expected, leaving us twenty minutes to board our next plane to Madrid. Just like Murphy’s law, our next gate was on the opposite side of the airport. Keep in mind that this is one of the three largest airports in Europe. The two of us were forced to run across the airport, but it turned out that they had already finished boarding the plane. After a little bit of persuasion, the gate attendant allowed us on last-minute. Another thing we were lucky with was the date we were in Italy (December 15th). A week after leaving, Italy banned travel for all Ukrainian citizens due to Covid.

Installs & Job-Sites

Over the seven-week journey, we completed two installs from start to finish. One was in Germany, and the other was in Zaragoza, Spain. We spent most of our time working at different job sites where we had to fix equipment for our client. Typically, we worked ten hours on-site, but then another three hours once we got back to the hotel. Our nights at the hotel were spent cutting, stripping, and crimping materials we needed for the next workday. The longest day I remember was when we arrived in Spain late in the evening after a full day of travel and had to begin preparation right away. We only got three hours of sleep that night before heading to the job site in the morning. Overall, we reworked 220 items, manually crimped 11,000 terminals, and used 1,400 meters of wire.

Sightseeing

We tried to see as much as possible during our hectic travel and work schedule. We didn’t have time for everything due to how often we had to move to our next city. We found time to take quick walks in the prominent locations, though. We saw the statue of Jeanne d’Arc, the Eiffel Tower, and so much more. Berlin, Milan, Orleans, Paris, and Madrid were all beautiful cities. My favorite spots were two small historical towns: Orleans, France, and Toledo, Spain (you can scroll through their photos at the bottom of this page or on the Logistics Plus Flickr Page).

Overall Experience

As we reflect on our journey across Europe, only the good moments remain in our memory. Overall, we had a great time and got everything done that we needed to. It was a successful seven weeks, but I wouldn’t say we are itching to get back on the road right away 🙂

After sharing the details of their experiences and travels, Oleh and Mykhailo wanted to emphasize that their success wouldn’t be possible without the help of others. Oleh said, “We were never alone. The whole trip, we had support from our teams around the world. Brian, Ben, Volodymyr, Michel, and Michal were big parts of these projects. A big thanks to all of them and the entire LP team!”

(Click the right and left arrows above to move through the slideshow)

by logisticsplus | Feb 17, 2022 | News

The Commodity Classifications Standards Board (CCSB) has published a new supplement to the National Motor Freight Classification (NMFC®). These NMFC changes are effective 04/09/2022. Some notable changes are listed below.

The Commodity Classifications Standards Board (CCSB) has published a new supplement to the National Motor Freight Classification (NMFC®). These NMFC changes are effective 04/09/2022. Some notable changes are listed below.

Subject 1 – Cookware, Items for cookware made of different metals and alloys were all combined into one item (52880) with a full density class grouping. 52890, 52895, 52896, and 52900 all were canceled.

Subject 3 – Detectors, Fire, Previous Items (61552 and 61555) established class based upon actual value. These items were canceled and replaced by 61550 which establishes a single class of 110.

Subject 4 – Ink, Dry Ink or Toner, Item 101740 was changed from a single class 70 to three density-based classes. Dry Ink Cartridges were removed from 116030 and added to 101740.

Subject 5 – Cables, mechanical control # 39510, Class changed from a straight 70 to a full density item.

Subject 6 – Fruits, Meats, Vegetables, and Dairy Products #76850. Density breaks and classes changed. See Revised Item.

Subject 7 – Cough Drops or Throat Lozenges, #58730, Class changed from 65 to 100

Subject 9 – Tape Friction or Insulating including electrical tape, Items 49450 and 49680 canceled and replaced with 49680 which is a full density scale.

Subject 10 – Oils, Cooking Oils and vegetable Shortening, Item 73238 revised to include Cooking Sprays. Still class 65.

Subject 13 – Door Lites, Sidelites, or transom Lites, Old item 34943 is canceled and replaced with 34250 which has 8 subs based on Dimensions and density.

Subject 14 – Bags, apparel, bedding, clothing, or garment storage, Item 20510 is canceled and replaced by 20580 which is a full-scale density item.

Subject 15 – Foodstuffs: Kernels or Seeds (pumpkin or sunflower), Kernels, and Seeds removed from Item 73238 and moved to new Item 73705 which has three classes based on density.

Subject 16 – Combs, Brushes, Crimpers, Fluters, Straighteners or Wavers; Irons or Wands, Item 61370 is canceled and rolled into Item 62290. Class on 62290 changed from 85 to 125.

Subject 17 – Bins or Shelving, Item 82360 – Bins or shelving is canceled and added to item 82270 – Metallic or Wooden Furniture, which is a full density item. Previously is it was either 150 or 70 depending upon SU or KD.

Subject 18 – Binoculars, Binoculars, Field glasses, opera glasses, etc…now a straight class 150. Class used to be dependent upon actual value.

Subject 21 – Egg Beaters, Item 100520 which was class 85 now canceled, and now egg beaters are part of Tools, hand, kitchen, NOI, a full density item.

Subject 22 – Bayonets, Swords, scabbards, Class changed from 100 to a three-class scale based upon density.

Subject 24 – Definition or Specifications for Crates

Subject 25 – Filters, cigarette, Item 69083, Class changed from 100 to 200.

Subject 26 – Explosives, Item 64300, Item amended to clarify that explosives moving under its provisions ‘must’ be transported in DOT authorized packaging.

Subject 27 – Hazardous materials, ORM-D removed since Shippers are no longer authorized to use these markings.

Subject 36 – Petroleum Xylidine, Item 155460, Item canceled. See Item 45615 – Poisonous or Toxic Materials.

by logisticsplus | Feb 16, 2022 | News

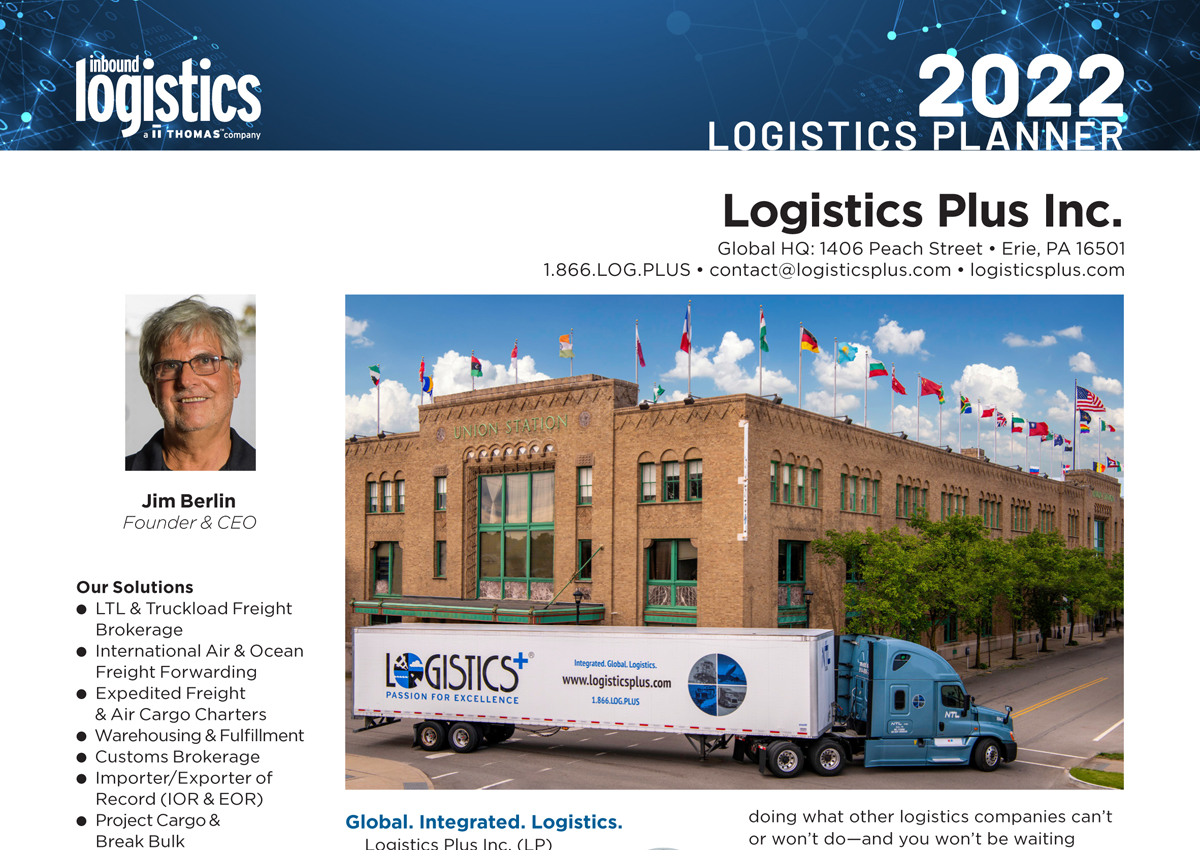

Logistics Plus has, once again, been profiled as a top third-party logistics (3PL) company by Inbound Logistics magazine for its annual Logistics Planner. In its 30th year of publication, the 2022 industry planner helps companies find the right technology solutions and transportation and logistics partners to drive supply chain efficiency. With both print and digital editions, the annual issue is updated with profiles of leaders in transportation, technology, logistics, and more who stand ready to help businesses face upcoming challenges to optimize their supply chains.

Logistics Plus has, once again, been profiled as a top third-party logistics (3PL) company by Inbound Logistics magazine for its annual Logistics Planner. In its 30th year of publication, the 2022 industry planner helps companies find the right technology solutions and transportation and logistics partners to drive supply chain efficiency. With both print and digital editions, the annual issue is updated with profiles of leaders in transportation, technology, logistics, and more who stand ready to help businesses face upcoming challenges to optimize their supply chains.

The Logistics Plus profile appears on page 348 of the publication, and an accompanying advertisement appears on page 137. The profile and advertisement formally present our new theme “Global Logistics + So Much More” as a follow-up to A 21st Century Logistics Company™ introduced last year.

Working as your 3PL, 3.5PL, or 4PL partner, Logistics Plus is the company that handles supply chain challenges from start to finish by doing what other logistics companies can’t or won’t do. We’re small enough to be agile and responsive to your needs, yet large enough to have a network of solutions that span your entire supply chain.

You can view PDF versions of the Logistics Plus profile and advertisement by clicking the two images below.

You can view the entire 2022 Logistics Planner digital edition online here: https://www.inboundlogistics.com/cms/digital/

by logisticsplus | Feb 15, 2022 | News

Congratulations to Ryan Markiewicz, Logistics Plus Marketing Specialist, on being named Ignite Marketer of the Week! Very cool! You can read the introduction below with a link to the full article at the bottom.

Read the rest of the article online at https://ignitevisibility.com/ryan-markiewicz-marketing-specialist-logisitcs-plus/

About Ignite Visibility

Launched in 2013, Ignite Visibility is a premier full-service digital marketing agency based in San Diego, CA. The Ignite Visibility mission is to provide the most effective digital marketing solutions in the industry, a high-touch customer experience, deliver results and use profits to reinvest in client success, employee success and the community. Ignite Visibility is one of the highest awarded digital marketing agencies in the industry, works with some of the biggest brands in the world and is a 4x Inc. 5000 company. Visit them online at ignitevisibility.com.

by logisticsplus | Feb 15, 2022 | News

FOR IMMEDIATE RELEASE

Logistics Plus Recognizes Six 2021 LTL Carriers of the Year

Dayton Freight, Estes Express, XPO Logistics, FedEx Freight, Ward Transport, and RIST Transport receive honors.

ERIE, PA (February 15, 2022) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, is recognizing six of its less-than-truckload (LTL) carrier-partners for superior performance in 2021. The annual awards are being presented as follows:

ERIE, PA (February 15, 2022) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, is recognizing six of its less-than-truckload (LTL) carrier-partners for superior performance in 2021. The annual awards are being presented as follows:

- Dayton Freight: Diamond Award. It’s the sixth consecutive year that Dayton has been honored.

- Estes Express: Titanium Award. It’s the fourth consecutive year that Estes has been honored.

- XPO Logistics: Platinum Award. It’s the second consecutive year that XPO has been honored.

- FedEx Freight: Gold Award. It’s the third time FedEx has been honored in the past four years.

- Ward Transport & Logistics: Silver Award. It’s the fourth time in the past five years that Ward has been honored.

- RIST Transport: Bronze Award. It’s the first year that RIST has been honored.

Watch this video on LP NAD Solutions.

The Logistics Plus North American Division (NAD) manages hundreds of thousand LTL shipments annually as a recognized top freight brokerage firm. It delivers LTL services through its proprietary eShipPlus™ and MyLogisticsPlus™ transportation management systems (TMS) – online platforms made available to customers and select freight agents and embedded with MyFreightTrends™ business intelligence dashboards. Logistics Plus also offers shippers truckload, expedited, international freight forwarding, claims management, freight audit & payment, business intelligence, plus many other supply chain solutions.

Logistics Plus works with over 50 carriers to deliver its LTL services. Annual LTL carrier awards are based on an assessment of the following performance criteria:

- Share of Business Volume & Growth

- Service, Claims & Billing Performance

- Price Competitiveness

- Customer Service & Support

- Account Representation & Partnership

“We value all of our carrier-partners, and picking to best-of-the-best each year is always difficult, which is why we have expanded this year’s awards to six levels,” said Scott Frederick, vice president of marketing and LTL carrier relations for Logistics Plus. “Despite operational and rate challenges brought on by the pandemic, capacity constraints, and weather patterns, Dayton, Estes, XPO, FedEx, Ward, and RIST all provided the best overall performance across most aspects of our partnership ratings, so I congratulate and thank each of them. We also look forward to our other great carriers challenging the incumbents for next year’s recognition.”

About Logistics Plus Inc.

Logistics Plus Inc. is a 21st-century logistics company that provides freight transportation, Warehousing, fulfillment, global logistics, business intelligence, and supply chain management solutions through a worldwide network of talented and caring professionals. The company was founded 25 years ago in Erie, PA, by Jim Berlin. Today, Logistics Plus is a highly regarded, fast-growing, and award-winning transportation and logistics company. With its trademark Passion For Excellence™, Logistics Plus employees put the ‘plus’ in logistics by doing the big things properly, plus the countless little things that ensure complete customer satisfaction and success.

Logistics Plus Inc. is a 21st-century logistics company that provides freight transportation, Warehousing, fulfillment, global logistics, business intelligence, and supply chain management solutions through a worldwide network of talented and caring professionals. The company was founded 25 years ago in Erie, PA, by Jim Berlin. Today, Logistics Plus is a highly regarded, fast-growing, and award-winning transportation and logistics company. With its trademark Passion For Excellence™, Logistics Plus employees put the ‘plus’ in logistics by doing the big things properly, plus the countless little things that ensure complete customer satisfaction and success.

The Logistics Plus® network includes offices, warehouses, and agents located in Erie, PA; Aurora, CO; Buffalo, NY; Chicago, IL; Chino, CA; Cincinnati, OH; Cleveland, OH; Dallas, TX; Dayton, NJ; Des Moines, IA; Haslet TX; Houston, TX; Laredo, TX; Lexington, NC; Los Angeles, CA; Miami, FL; New York, NY; Olean, NY; San Francisco, CA; Australia; Belgium; Brazil; Canada; China; Colombia; Czech Republic; Egypt; France; Germany; India; Indonesia; Japan; Kazakhstan; Kenya; Libya; Mexico; Netherlands; Poland; Saudi Arabia; Singapore; Taiwan; Turkey; UAE; Uganda; and Ukraine; with additional agents around the world. For more information, visit www.logisticsplus.com or follow @LogisticsPlus on Twitter.

Media Contact:

Scott G. Frederick

Vice President, Marketing

Logistics Plus Inc.

(814) 240-6881

scott.frederick@logisticsplus.com

Click the image below to download the Logistics Plus logo:

Logistics Plus (LP) is pleased to announce that the Florida Department of Business & Professional Regulation (Florida DBPR) has granted a license to its Miami, Florida warehouse for the public storage of alcoholic beverages and spirits.

Logistics Plus (LP) is pleased to announce that the Florida Department of Business & Professional Regulation (Florida DBPR) has granted a license to its Miami, Florida warehouse for the public storage of alcoholic beverages and spirits.

Over a seven-week time frame, Logistics Plus employees

Over a seven-week time frame, Logistics Plus employees

ERIE, PA (February 15, 2022) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, is recognizing six of its less-than-truckload (LTL) carrier-partners for superior performance in 2021. The annual awards are being presented as follows:

ERIE, PA (February 15, 2022) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, is recognizing six of its less-than-truckload (LTL) carrier-partners for superior performance in 2021. The annual awards are being presented as follows:

Logistics Plus Inc. is

Logistics Plus Inc. is