by logisticsplus | Sep 5, 2017 | News

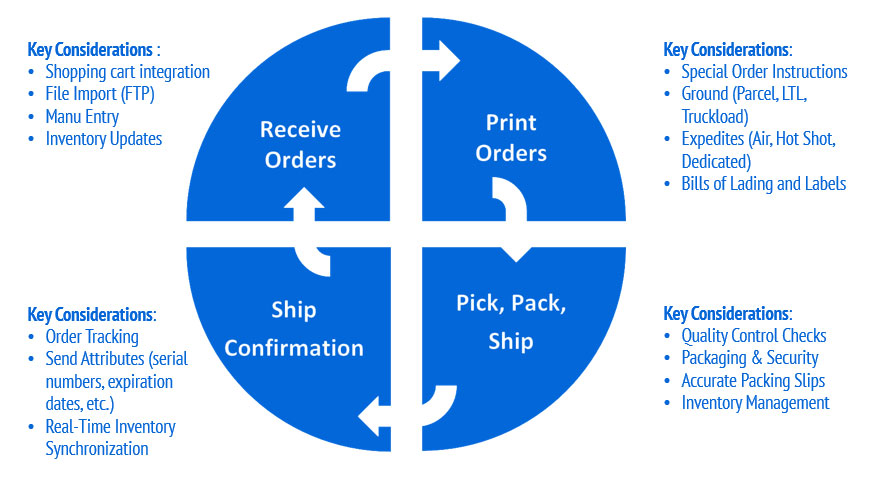

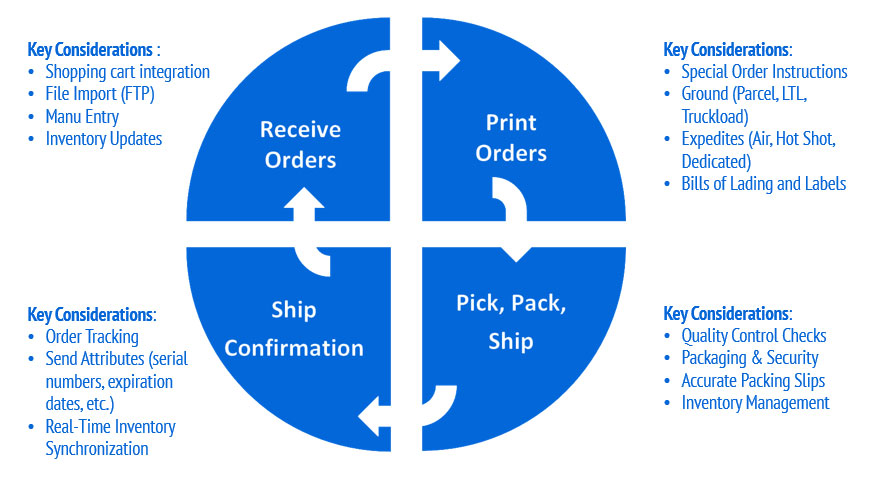

When growing a company, you may reach the point where you can no longer handle all of your customers’ order needs. When this time arrives, companies need to consider outsourcing pick, pack, and ship fulfillment services to a third-party specialist. “Pick, pack, and ship” in its simplest terms means receiving customer orders, selecting the correct item out of your inventory, choosing the correct packaging, and shipping the order to your customer. Outsourcing this process to a third-party fulfillment company, such as Logistics Plus, can help you grow and expand your e-commerce business much faster than doing so on your own. However, there are important considerations that come into play at each step in the process. Addressing each of these areas requires a third-party partner that can full integrate itself into your shopping cart or order management system, has the knowledge on which transportation modes and packaging are best for your products, and can provide the necessary tracking, follow-up and real-time inventory management updates you’ll need to stay current.

When growing a company, you may reach the point where you can no longer handle all of your customers’ order needs. When this time arrives, companies need to consider outsourcing pick, pack, and ship fulfillment services to a third-party specialist. “Pick, pack, and ship” in its simplest terms means receiving customer orders, selecting the correct item out of your inventory, choosing the correct packaging, and shipping the order to your customer. Outsourcing this process to a third-party fulfillment company, such as Logistics Plus, can help you grow and expand your e-commerce business much faster than doing so on your own. However, there are important considerations that come into play at each step in the process. Addressing each of these areas requires a third-party partner that can full integrate itself into your shopping cart or order management system, has the knowledge on which transportation modes and packaging are best for your products, and can provide the necessary tracking, follow-up and real-time inventory management updates you’ll need to stay current.

If you’re still on the fence, here are additional reasons why you might consider outsourcing your pick, pack, and ship fulfillment services:

Organization and Speed

The main concern of most companies is customer satisfaction. With that being said, being organized and quick to pick and pack orders only means that a customer will receive their products faster. Third-party fulfillment companies are experienced and know what it takes to correctly fulfill an order in a timely fashion.

Lower Overhead and Fixed Costs

As your business expands, you may consider renting or purchasing a warehouse with enough space to store your inventory, while leaving enough room for the fulfillment process. As you can imagine, renting or purchasing a warehouse can be extremely costly. At that point, you will also need someone to run the operation, costing you more money, no matter the number of orders placed. By outsourcing to a fulfillment company, you can avoid several of these fixed costs and focus more on building your brand and selling your products.

Scalability

Outsourcing your pick, pack, and ship fulfillment services allows you the flexibility to grow your company as it grows with you. Fulfillment companies already have a large client base they fulfill orders for daily. This means that if your business triples in size, it will be much easier for a fulfillment company to adjust to the new volume of your orders, rather than you trying to adjust yourself.

Technology Solutions

A third-party logistics company often provides beneficial technology solutions that help level the playing field. Two of these specific systems include warehouse management system (WMS) and transportation management system (TMS). These systems can add tremendous value to your company because they provide detailed information regarding inventory, upcoming trends, and rate analysis through a web-based program. These technology solutions can cost hundreds of thousands of dollars, but can be available to you just by outsourcing to the right pick, pack, and ship fulfillment service.

Shipping from Ideal Locations

Most large 3PL’s have several locations throughout the country and sometimes world. Since shipping carriers base rates on location and time of delivery, having an ideal location for your product inventory can be crucial. This will save money on shipping, while saving time the customers must wait to receive their order. Outsourcing fulfillment services to ideal warehouse and fulfillment locations will also help you expand your business and help you reach markets and places you may not have thought were possible.

By outsourcing your pick, pack, and ship fulfillment services, you may be able to save time and money, while allowing you to focus on the most important parts of your business: selling products and building your brand! Logistics Plus is ready and willing to assist you with all of your e-commerce fulfillment needs.

by logisticsplus | Aug 23, 2017 | News

Logistics Plus (LP) India recently opened a new and improved Bengaluru office. The LP Bengaluru branch manager is Renu Chandrashekar, and Ranjith Kumar is the senior executive over operations. Bengaluru (also called Bangalore) is the capital of India’s southern Karnataka state. It is considered the Silicon Valley of India and is the nation’s top Information Technology (IT) exporter, contributing 33% of India’s software services exports. Bengaluru is the third highest populated city in India and the sixth-highest populated urban agglomeration. In the past decade, Bengaluru has experienced a growth rate of 38%, second only to the region of New Delhi. Some of the top IT companies include Infosys, TCS, and Wipro. Bengaluru has many multinational corporations located there, such as IBM, Phillips, Siemens, General Electric, and Boeing.

Logistics Plus India – an important and growing division of our global network — now has six offices located across the country.

Logistics Plus India Pvt Ltd – Bengaluru

J-22, Global Incubation Services, CA site

No-1 JSS Institutions Campus, Hal 3rd Stage

Behind Leela Palace, Kodihalli, Bengaluru

Karnataka-560008

Mobile No.- +91-88844-78802

Fetching directions......

by logisticsplus | Aug 23, 2017 | News

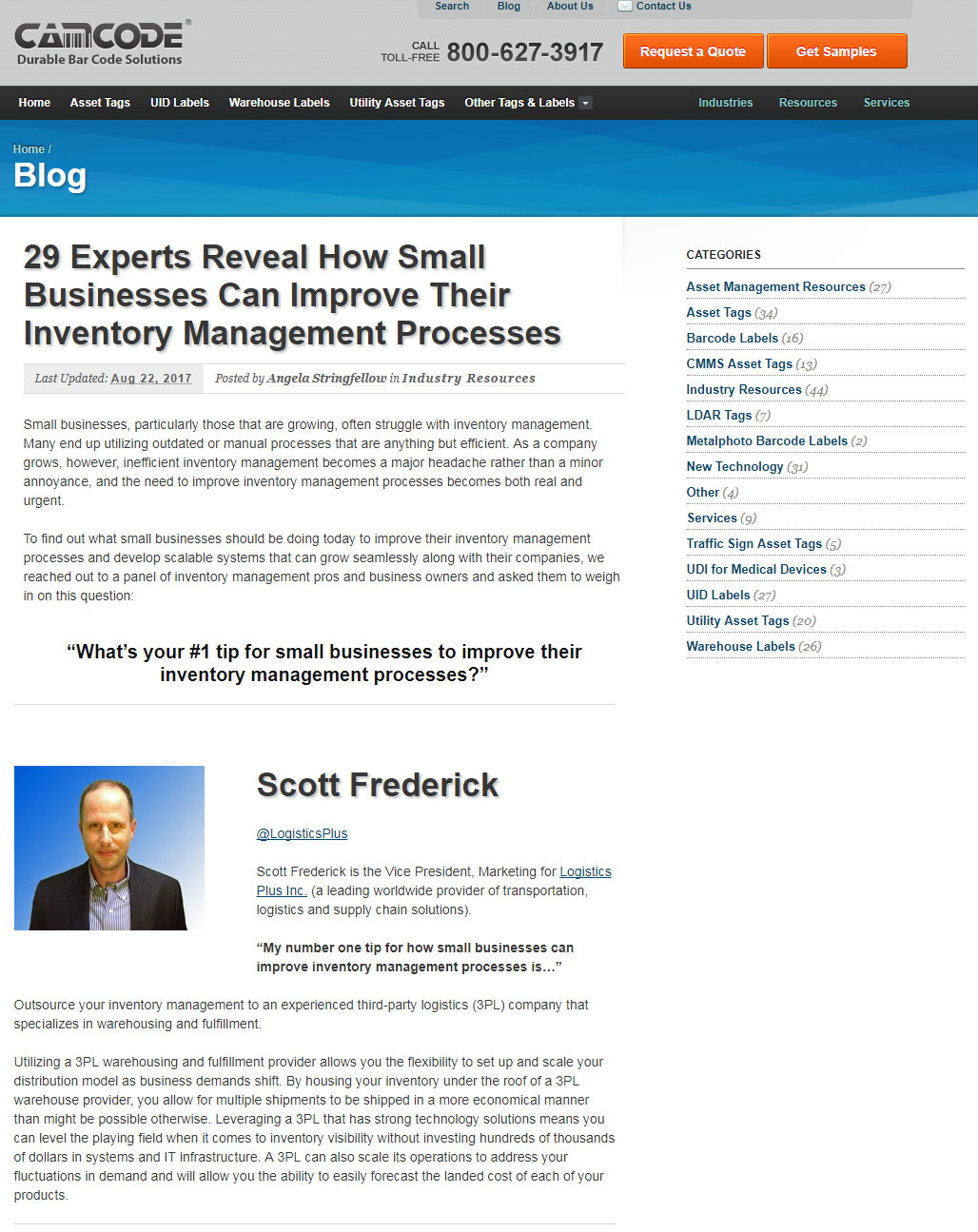

Thank you to the folks at Camcode for including Logistics Plus in their recent “How Small Businesses Can Improve Their Inventory Management Processes” blog post by Angela Stringfellow. As part of the post, 29 industry experts were asked the question “What’s your #1 tip for small businesses to improve their inventory management processes?” The full article can be viewed online, and the excerpt that includes comments from Scott Frederick, VP of marketing for Logistics Plus, can be viewed below. Founded in 1979, Camcode® designs and manufactures durable pre-printed bar code labels and customized services for asset tracking applications utilizing automatic identification and data capture.

by logisticsplus | Aug 16, 2017 | News

Logistics Plus recently recorded two new webinars as part of its ongoing series of complimentary logistics-related webinars for the Manufacturer & Business Association (MBA) and its members. The two new webinars are focused on Importing Basics and Exporting Basics. Although these webinars are prepared for the benefit of MBA members, the informational content is appropriate for any business that is, or will be, importing or exporting products. Past webinars cover additional transportation and logistics topics. Logistics Plus is the company that manages the MBA Logistics Program. You can learn more about the program at www.mbausa.org/logistics.

Logistics Plus recently recorded two new webinars as part of its ongoing series of complimentary logistics-related webinars for the Manufacturer & Business Association (MBA) and its members. The two new webinars are focused on Importing Basics and Exporting Basics. Although these webinars are prepared for the benefit of MBA members, the informational content is appropriate for any business that is, or will be, importing or exporting products. Past webinars cover additional transportation and logistics topics. Logistics Plus is the company that manages the MBA Logistics Program. You can learn more about the program at www.mbausa.org/logistics.

Importing Basics:

Exporting Basics:

by logisticsplus | Aug 9, 2017 | News

Earlier today, Pennsylvania Governor Tom Wolf visited Logistics Plus to meet with employees and view the company’s plans for the expansion of its global headquarters at the historic Union Station in the City of Erie. Erie County Executive, Kathy Dahlkemper, and other local officials were also on hand.

“It’s exciting to be in Erie touring another thriving company,” said Governor Wolf. “I am committed to supporting the growing business climate in the region and love to see first-hand what an innovative company like Logistics Plus has planned for the future.”

Coordinated by the Governor’s Action Team, last month, Logistics Plus announced its plans to expand and create 44 new, family-sustaining jobs in Erie. Today, the governor toured the company’s facility and planned expansion site. The expanded facility will allow for the handling of all logistics for clients, from order intake to shipping and installation.

“Logistics Plus has grown from a three-person operation in 1996, to a global organization, employing over 130 people in Erie alone. We are grateful to Governor Wolf and the commonwealth for acknowledging our efforts to attract and retain local graduates,” commented Gretchen Seth, Senior VP of International. “Our CEO Jim Berlin calls it the ‘brain gain’.”

*************************************

Local media provided additional coverage:

On ‘Jobs That Pay’ Tour, Governor Wolf Visits Logistics Plus Inc. via the Governor Wolf Newsroom

Governor Tom Wolf to visit Erie via YourErie.com

Governor Tom Wolf to visit Erie via ErieNewsNow.com

Governor’s Visit Highlights Growth, Challenges for Erie via GoErie.com

Logistics Plus Expansion Project via YourErie.com

by logisticsplus | Aug 9, 2017 | News

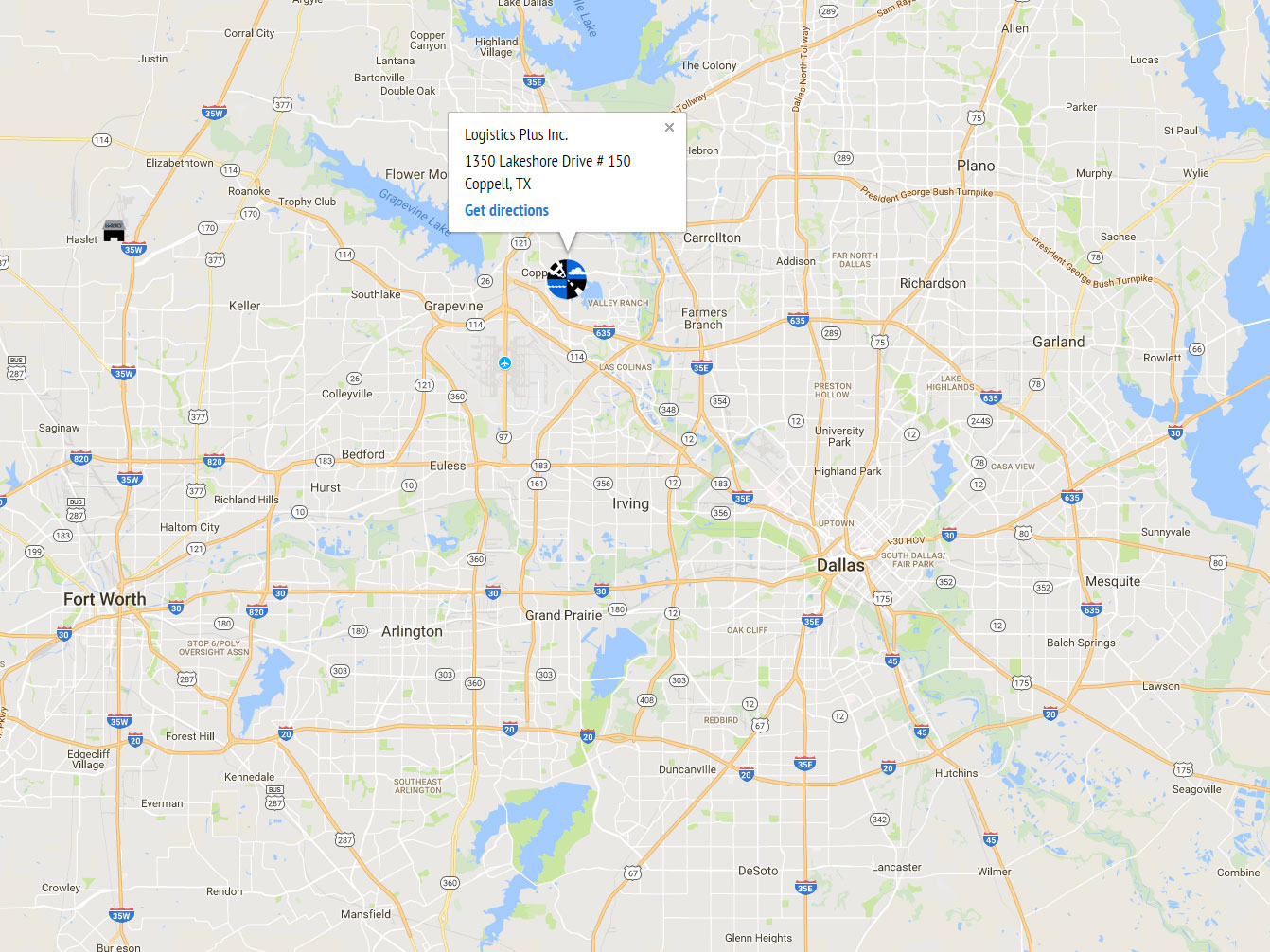

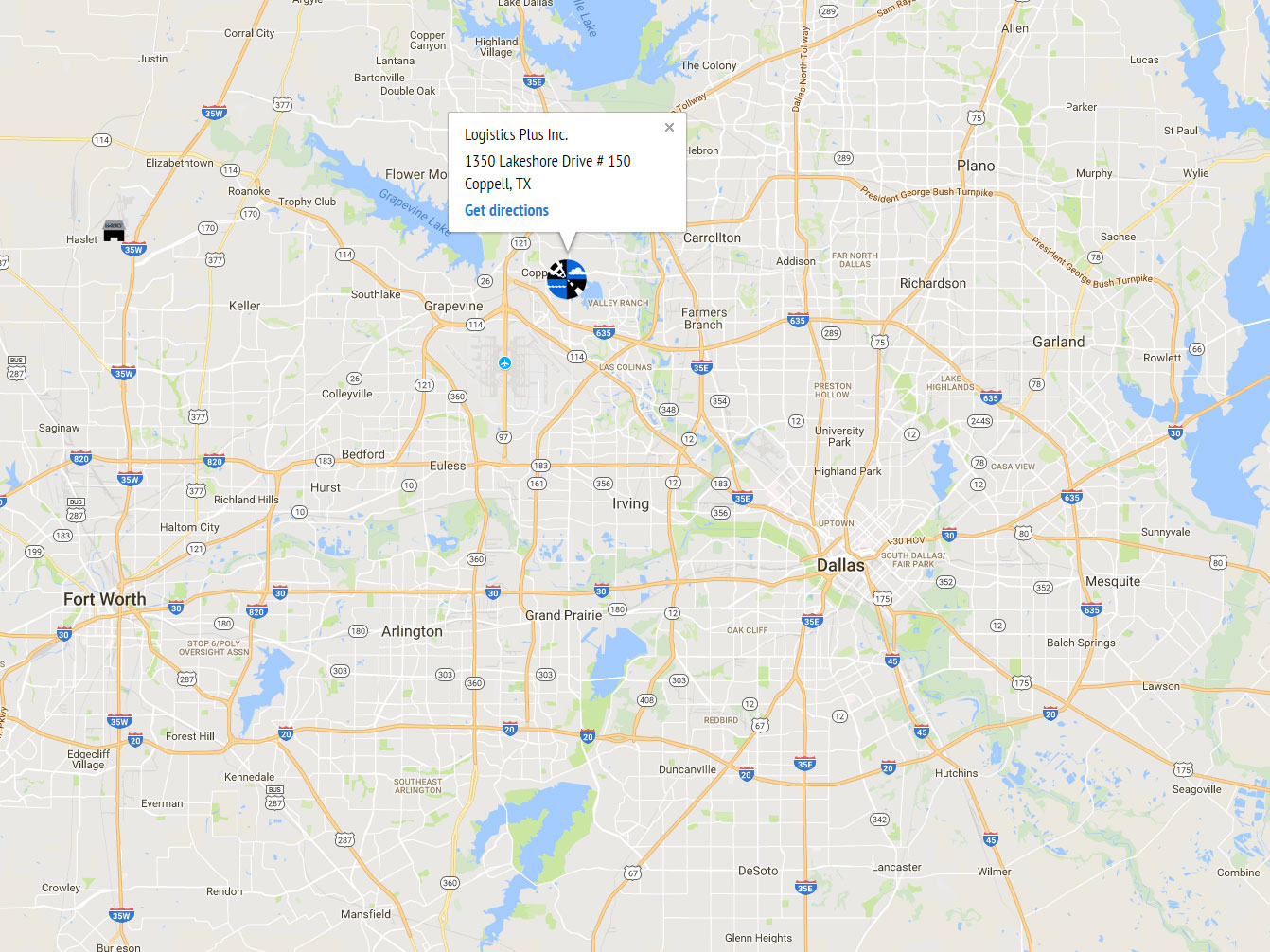

Please note, the Logistics Plus Dallas office will be moving from 8600 Freeport Parkway to 1350 Lakeshore Drive, Suite #150 in Coppell, TX on August 12th. All of our phone numbers and email addresses will remain the same. Just to confirm, here is our new full address and contact information:

Logistics Plus Inc. – Dallas Office

1350 Lakeshore Drive #150

Coppell, TX 75019

Main Phone: 877.447.9564

Main Fax: 972.550.6102

Email: dallas@logisticsplus.com

Jenny Melgert, Dallas Branch Manager

The Dallas office move above does not impact our DFW warehouse location in Haslet. The DFW address and contact information remain the same as follows:

Logistics Plus Inc. – DFW Warehouse and FTZ

920 Westport Parkway

Haslet, TX 76177

Phone: 972.893.9695

Email: pricing@logisticsplus.com

Sabrina Ragland, Warehouse Administrator

Thank you for your business and loyalty!

Logistics Plus Inc.

www.logisticsplus.com

When growing a company, you may reach the point where you can no longer handle all of your customers’ order needs. When this time arrives, companies need to consider outsourcing pick, pack, and ship fulfillment services to a third-party specialist. “Pick, pack, and ship” in its simplest terms means receiving customer orders, selecting the correct item out of your inventory, choosing the correct packaging, and shipping the order to your customer. Outsourcing this process to a third-party fulfillment company, such as Logistics Plus, can help you grow and expand your e-commerce business much faster than doing so on your own. However, there are important considerations that come into play at each step in the process. Addressing each of these areas requires a third-party partner that can full integrate itself into your shopping cart or order management system, has the knowledge on which transportation modes and packaging are best for your products, and can provide the necessary tracking, follow-up and real-time inventory management updates you’ll need to stay current.

When growing a company, you may reach the point where you can no longer handle all of your customers’ order needs. When this time arrives, companies need to consider outsourcing pick, pack, and ship fulfillment services to a third-party specialist. “Pick, pack, and ship” in its simplest terms means receiving customer orders, selecting the correct item out of your inventory, choosing the correct packaging, and shipping the order to your customer. Outsourcing this process to a third-party fulfillment company, such as Logistics Plus, can help you grow and expand your e-commerce business much faster than doing so on your own. However, there are important considerations that come into play at each step in the process. Addressing each of these areas requires a third-party partner that can full integrate itself into your shopping cart or order management system, has the knowledge on which transportation modes and packaging are best for your products, and can provide the necessary tracking, follow-up and real-time inventory management updates you’ll need to stay current.