by logisticsplus | Sep 17, 2020 | News

Logistics Plus has once again partnered with WPSE AM 1450/FM 107.1 Radio to bring a full slate of area high school, college, and NFL football games to radio airwaves in Erie, Pennsylvania. As a presenting sponsor, Logistics Plus will be mentioned prominently throughout each broadcast starting with tonight’s Browns game at 5:15 pm. All broadcasts can be heard locally on AM 1450 or FM 107.1. The sponsorship is a natural fit for Logistics Plus which has been a marquee sponsor for Best of Varsity Cup the past four years: the annual event that celebrates and honors the accomplishments of District 10 All-Area high school student-athletes and top performers.

Logistics Plus has once again partnered with WPSE AM 1450/FM 107.1 Radio to bring a full slate of area high school, college, and NFL football games to radio airwaves in Erie, Pennsylvania. As a presenting sponsor, Logistics Plus will be mentioned prominently throughout each broadcast starting with tonight’s Browns game at 5:15 pm. All broadcasts can be heard locally on AM 1450 or FM 107.1. The sponsorship is a natural fit for Logistics Plus which has been a marquee sponsor for Best of Varsity Cup the past four years: the annual event that celebrates and honors the accomplishments of District 10 All-Area high school student-athletes and top performers.

Audio clips for three of the Logistics Plus “commercials” that will air during the games can be listened to below.

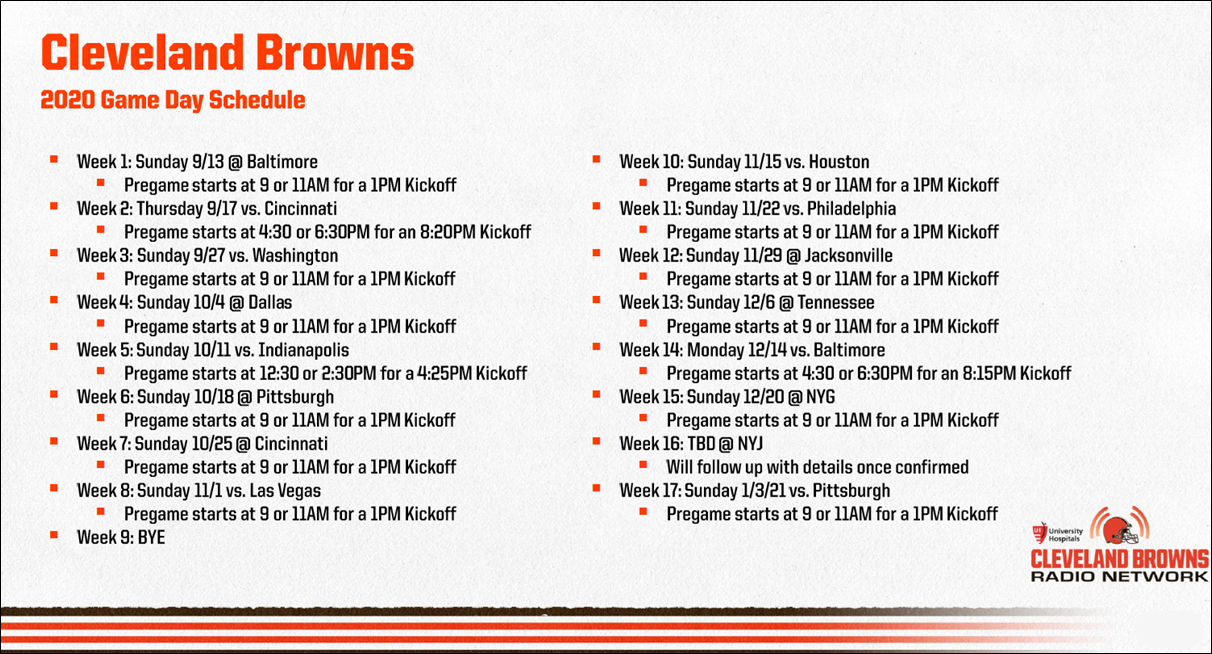

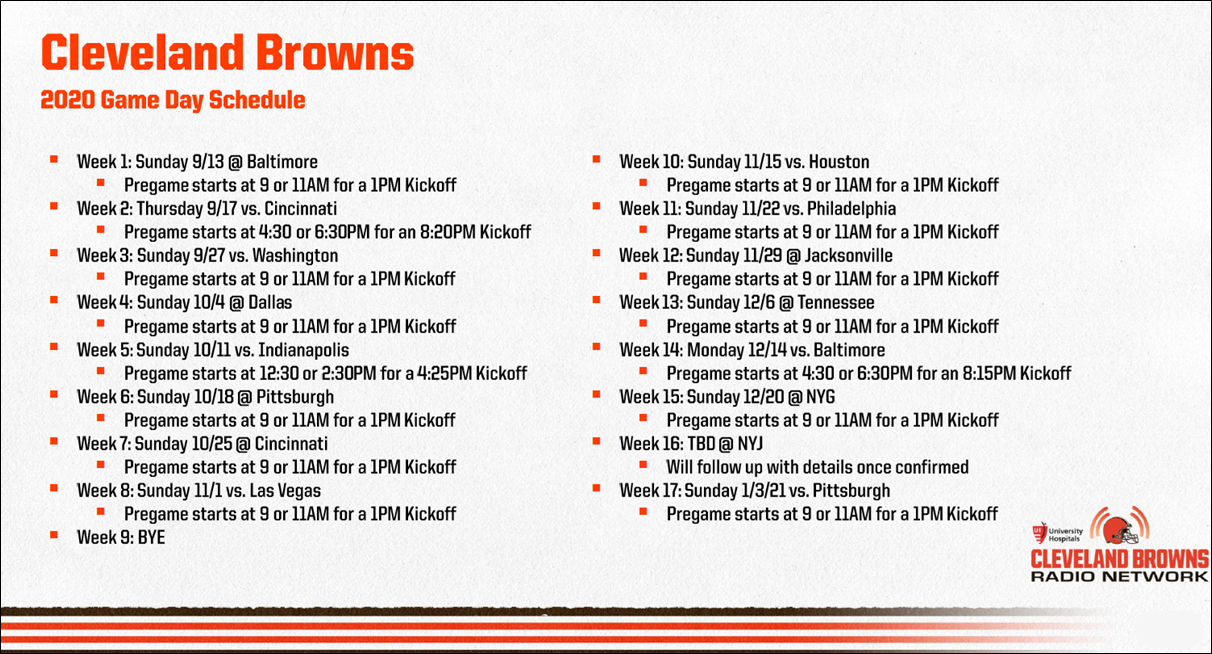

The Logistics Plus sponsorship will entail over 100 football games, including 19 high school games (see schedule below), 9 Penn State University college games (schedule TBD), 15 Cleveland Browns games (see schedule below), and 59 additional NFL games (schedule TBD)!

by logisticsplus | Sep 17, 2020 | News

FOR IMMEDIATE RELEASE

Logistics Plus Renews Its Annual U.S. EPA SmartWay Transport® Partnership

It’s the tenth consecutive year that Logistics Plus successfully completes its SmartWay emissions reporting.

ERIE, PA (September 17, 2020) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, is proud to announce that it has submitted and received approval for its current data submission to the SmartWay Transport Partnership, an innovative collaboration between the U.S. Environmental Protection Agency (EPA) and the industry.

ERIE, PA (September 17, 2020) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, is proud to announce that it has submitted and received approval for its current data submission to the SmartWay Transport Partnership, an innovative collaboration between the U.S. Environmental Protection Agency (EPA) and the industry.

Since 2004, SmartWay has helped partners avoid emitting 134 million tons of air pollution (NOx, PM, and CO2), which helps protect the environment and keep Americans healthy. Emissions reductions benefit communities near ports, borders, and truck stops, protecting the health and well-being of citizens in these areas. Each year, performance data is submitted and reviewed to qualify as a SmartWay partner. The EPA recently approved the Logistics Plus annual submission of Partnership reporting requirements for the tenth consecutive year.

“The U.S. Environmental Protection Agency (EPA) applauds the renewal of your SmartWay partnership and looks forward to working with you to achieve your freight efficiency goals,” said Langston Jones, Partner Account Manager Assisting the EPA SmartWay Transport Partnership under a Cooperative Agreement with SSAI.

Adam Mook, Compliance Department Manager for Logistics Plus, added, “Our partnership with SmartWay the past decade is another confirmation to our customers and carriers that Logistics Plus is doing its part for environmental sustainability.”

Learn more at www.logisticsplus.com/logistics-plus-sustainability-initiatives.

About SmartWay

Audio Comments for WPSE Radio

In 2004, fifteen companies and freight sector associations worked with U.S. Environmental Protection Agency (EPA) to create the SmartWay program as a way of using market-based incentives and technology solutions to address long-term trends, changes, and challenges in the freight transportation sector. SmartWay Transport is the U.S. EPA’s flagship program for improving fuel efficiency and reducing greenhouse gases and air pollution from the transportation supply chain industry. The Partnership currently has over 3,700 Partners including shipper, logistics companies, truck, rail, barge, and multimodal carriers. Partners rely upon SmartWay tools and approaches to track and reduce emissions and fuel use from goods movement. For information about the SmartWay Transport Partnership visit www.epa.gov/smartway.

About Logistics Plus Inc.

Logistics Plus Inc. provides freight transportation, warehousing, fulfillment, global logistics, business intelligence technology, and supply chain management solutions through a worldwide network of talented and caring professionals. The company was founded over 24 years ago in Erie, PA by local entrepreneur, Jim Berlin. Today, Logistics Plus is a highly regarded, fast-growing, and, award-winning transportation and logistics company. With a strong passion for excellence, its 450 global employees put the “plus” in logistics by doing the big things properly, plus the countless little things, that together ensure complete customer satisfaction and success.

Media Contact:

Scott G. Frederick

Vice President, Marketing

Logistics Plus Inc.

(814) 240-6881

scott.frederick@logisticsplus.com

Click the image below to download the Logistics Plus logo:

by logisticsplus | Sep 16, 2020 | News

The Logistics Plus Medical team – or LP Med for short – has added several items to their already expansive line of personal protective equipment (PPE). The LP Med team has already sourced and delivered over 12 million reliable and FDA-approved PPE supplies to organizations and businesses in need around the world. As a part of our ongoing efforts to help fight the battle against COVID-19 (and as outlined in the video below), we are selling surgical masks, KN95 masks, children’s masks, face shields, gloves, goggles, hand sanitizers, thermometers, and much more.

The Logistics Plus Medical team – or LP Med for short – has added several items to their already expansive line of personal protective equipment (PPE). The LP Med team has already sourced and delivered over 12 million reliable and FDA-approved PPE supplies to organizations and businesses in need around the world. As a part of our ongoing efforts to help fight the battle against COVID-19 (and as outlined in the video below), we are selling surgical masks, KN95 masks, children’s masks, face shields, gloves, goggles, hand sanitizers, thermometers, and much more.

Don’t take our word for it, read testimonials from our happy and satisfied customers here: www.logisticsplus.com/PPE-testimonials

by logisticsplus | Sep 15, 2020 | News

FOR IMMEDIATE RELEASE

Logistics Plus Acquires Rights to www.logisticsplus.com Domain

The company’s website can now be found online at either www.logisticsplus.com or www.logisticsplus.com.

ERIE, PA (September 15, 2020) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics, and supply chain solutions, reports that it has acquired the lawful rights to the www.logisticsplus.com domain name. In accordance with ICANN’s Uniform Domain Name Dispute Resolution Policy, a formal “Logistics Plus, Inc. v. Silverman, Jay” Complaint was filed on July 8, 2020. A three-person panel appointed by the FORUM, a third-party arbitration service, on August 18, 2020, made the decision that Logistics Plus should rightfully be awarded the www.logisticsplus.com domain name.

The company expects to migrate its primary URL and all email addresses to the www.logisticsplus.com domain in the near future.

“We are pleased with the FORUM’s decision,” said Scott Frederick, Vice President of Marketing for Logistics Plus. “As the rightful owners of the Logistics Plus name and marks, and after years of unsuccessful good-faith negotiations, we filed a formal complaint because we felt strongly that we should own the rights to both the dot net and dot com domain name variations of our trademarked name. It’s unclear how many people tried and failed to find us over the years through the dot com extension, but I am delighted they will be able to find us now.”

About Logistics Plus Inc.

Logistics Plus Inc. provides freight transportation, warehousing, fulfillment, global logistics, business intelligence technology, and supply chain management solutions through a worldwide network of talented and caring professionals. The company was founded over 24 years ago in Erie, PA by local entrepreneur, Jim Berlin. Today, Logistics Plus is a highly regarded, fast-growing, and, award-winning transportation and logistics company. With a strong passion for excellence, its 450 global employees put the “plus” in logistics by doing the big things properly, plus the countless little things, that together ensure complete customer satisfaction and success.

The Logistics Plus® network includes offices or warehouses located in Erie, PA; Akron, OH; Baltimore, MD; Birmingham, AL; Buffalo, NY; Chicago, IL; Cleveland, OH; Dallas, TX; Des Moines, IA; Detroit, MI; Fort Worth, TX; Haslet TX; Houston, TX; Laredo, TX; Lexington, NC; Los Angeles, CA; Melbourne, FL; Nashville, TN; New York, NY; Olean, NY; Ontario, CA; San Bernardino, CA; San Francisco, CA; Tampa Bay, FL; Australia; Bahrain; Belgium; Canada; China; Colombia; Czech Republic; Egypt; France; Germany; India; Indonesia; Japan; Kazakhstan; Kenya; Libya; Mexico; Netherlands; Poland; Saudi Arabia; Singapore; South Africa; Taiwan; Turkey; UAE; Ukraine; Uganda; and United Kingdom; with additional agents around the world. For more information, visit www.logisticsplus.com or follow @LogisticsPlus on Twitter.

Media Contact:

Scott G. Frederick

Vice President, Marketing

Logistics Plus Inc.

(814) 240-6881

Click the image below to download the Logistics Plus logo:

by logisticsplus | Sep 14, 2020 | News

This week, September 13-19, 2020, is National Truck Driver Appreciation Week (NTDAW). This year especially, Logistics Plus (which was founded and is owned by a former truck driver) and its sister company, National Truckload (NTL), would like to thank the 3.5 million professional men and women that have executed the crucial role of delivering goods during the COVID-19 pandemic. These truck drivers undertake one of our economy’s most demanding and important jobs – delivering our goods safely, securely, and on time. We ask that you please join us this week to celebrate and honor our truck drivers for all of their hard work and dedication.

This week, September 13-19, 2020, is National Truck Driver Appreciation Week (NTDAW). This year especially, Logistics Plus (which was founded and is owned by a former truck driver) and its sister company, National Truckload (NTL), would like to thank the 3.5 million professional men and women that have executed the crucial role of delivering goods during the COVID-19 pandemic. These truck drivers undertake one of our economy’s most demanding and important jobs – delivering our goods safely, securely, and on time. We ask that you please join us this week to celebrate and honor our truck drivers for all of their hard work and dedication.

With the historic COVID-19 pandemic inflicting negative economic conditions on our country, the men and women of the trucking industry have made personal sacrifices and risked exposure to the virus to help fuel our nation’s response. Our drivers have delivered ventilators and other medical equipment to hospitals, distributed cleaning products across the country, and delivered personal protective equipment to businesses in need. Lastly, our truck drivers ensure that food and other necessities remain available to consumers across the country. While it’s impossible to individually recognize each driver, we thank you for your crucial role in keeping our society moving forward during these challenging times.

With the historic COVID-19 pandemic inflicting negative economic conditions on our country, the men and women of the trucking industry have made personal sacrifices and risked exposure to the virus to help fuel our nation’s response. Our drivers have delivered ventilators and other medical equipment to hospitals, distributed cleaning products across the country, and delivered personal protective equipment to businesses in need. Lastly, our truck drivers ensure that food and other necessities remain available to consumers across the country. While it’s impossible to individually recognize each driver, we thank you for your crucial role in keeping our society moving forward during these challenging times.

TRUCKING INDUSTRY FACTS AND FIGURES:

- In 2018, the trucking industry hauled 11.49 billion tons of freight

- More than 80% of U.S. communities depend solely on trucking for delivery of their goods and commodities

- In 2018, the trucking industry was a $796.7 billion industry

- There are 3.5 million truck drivers in the U.S. and the total industry employment is 7.8 million

- Over 40% of all jobs in the trucking industry are held by women and minorities

To learn more about National Truck Driver Appreciation Week, visit the America Trucking Association (ATA) website here: www.trucking.org/NTDAW-2020

by logisticsplus | Sep 14, 2020 | News

Global Trade Alert Message:

Global Trade Alert Message:

In response to the United States’ recent tariffs on certain aluminum products from Canada, Canada will impose surtaxes against imports of U.S. aluminum. Canada has stated that select aluminum goods will be subject to a 10 percent surtax – a proportionate amount in comparison to the products affected by the U.S. tariffs. These countermeasures will only apply to goods originating in the U.S. and will take effect on September 16th. Canada has stated that the tariffs will remain in place until the United States eliminates its tariffs against Canada.

The list of products outlined in the tariffs can be found here: www.canada.ca/us-aluminum-products

Visit the Department of Finance Canada here: www.canada.ca/department-finance

Logistics Plus has once again partnered with WPSE AM 1450/FM 107.1 Radio to bring a full slate of area high school, college, and NFL football games to radio airwaves in Erie, Pennsylvania. As a presenting sponsor, Logistics Plus will be mentioned prominently throughout each broadcast starting with tonight’s Browns game at 5:15 pm. All broadcasts can be heard locally on AM 1450 or FM 107.1. The sponsorship is a natural fit for Logistics Plus which has been a marquee sponsor for Best of Varsity Cup the past four years: the annual event that celebrates and honors the accomplishments of District 10 All-Area high school student-athletes and top performers.

Logistics Plus has once again partnered with WPSE AM 1450/FM 107.1 Radio to bring a full slate of area high school, college, and NFL football games to radio airwaves in Erie, Pennsylvania. As a presenting sponsor, Logistics Plus will be mentioned prominently throughout each broadcast starting with tonight’s Browns game at 5:15 pm. All broadcasts can be heard locally on AM 1450 or FM 107.1. The sponsorship is a natural fit for Logistics Plus which has been a marquee sponsor for Best of Varsity Cup the past four years: the annual event that celebrates and honors the accomplishments of District 10 All-Area high school student-athletes and top performers.![]()

The Logistics Plus Medical team – or LP Med for short – has added several items to their already expansive line of personal protective equipment (PPE). The LP Med team has already sourced and delivered over 12 million reliable and FDA-approved PPE supplies to organizations and businesses in need around the world. As a part of our ongoing efforts to help fight the battle against COVID-19 (and as outlined in the video below), we are selling surgical masks, KN95 masks, children’s masks, face shields, gloves, goggles, hand sanitizers, thermometers, and much more.

The Logistics Plus Medical team – or LP Med for short – has added several items to their already expansive line of personal protective equipment (PPE). The LP Med team has already sourced and delivered over 12 million reliable and FDA-approved PPE supplies to organizations and businesses in need around the world. As a part of our ongoing efforts to help fight the battle against COVID-19 (and as outlined in the video below), we are selling surgical masks, KN95 masks, children’s masks, face shields, gloves, goggles, hand sanitizers, thermometers, and much more.

With the historic COVID-19 pandemic inflicting negative economic conditions on our country, the men and women of the trucking industry have made personal sacrifices and risked exposure to the virus to help fuel our nation’s response. Our drivers have delivered ventilators and other medical equipment to hospitals, distributed cleaning products across the country, and delivered

With the historic COVID-19 pandemic inflicting negative economic conditions on our country, the men and women of the trucking industry have made personal sacrifices and risked exposure to the virus to help fuel our nation’s response. Our drivers have delivered ventilators and other medical equipment to hospitals, distributed cleaning products across the country, and delivered