by logisticsplus | May 15, 2017 | News

Here is another cool cargo project involving the Logistics Plus Belgium team through our partnership with Carl Polzin.

Here is another cool cargo project involving the Logistics Plus Belgium team through our partnership with Carl Polzin.

The first part of the shipment saw 5 girders of 7 meter wide and 95mt being trucked to Mannheim barge terminal, loaded to barge, shipped to Rotterdam. The second part of the shipment saw 4 stanchions of 5.1 meter high and 72mt that could not be trucked to Mannheim, but only to Gernsheim and even then a ‘flyover bridge reinforcement’ (to put a steel bridge atop the actual bridge to strengthen it) had to be used to allow the heavy load to cross that bridge. Then all the cargo was shipped from Rotterdam to Thessaloniki and from there by truck to site.

The project is summarized in the photo collage below. You can also click the Case Study icon to download a PDF summary of the project.

by logisticsplus | May 5, 2017 | News

Logistics Plus Takes First Place in the Breakbulk “Into the Wild” Photo Contest

Photo was displayed at Breakbulk Europe 2017 conference and in Breakbulk magazine.

ERIE, PA (May 5, 2017) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics and supply chain solutions, is proud to announce it was awarded first place in the 2017 Breakbulk “Into the Wild” Photo Contest. Logistics Plus was presented with the award at the Breakbulk Europe 2017 conference which took place April 24-26 in Antwerp, Belgium.

ERIE, PA (May 5, 2017) – Logistics Plus Inc., a leading worldwide provider of transportation, logistics and supply chain solutions, is proud to announce it was awarded first place in the 2017 Breakbulk “Into the Wild” Photo Contest. Logistics Plus was presented with the award at the Breakbulk Europe 2017 conference which took place April 24-26 in Antwerp, Belgium.

The winning photograph, taken and submitted by the Logistics Plus Turkey division, was entitled “Winter Is Coming” and depicts a unique perspective of a steep tank being ocean transported. The cargo was being shipped from Istanbul to a factory in Orhangazi, Turkey. Due to snowy conditions and other factors, the cargo was uniquely transported on a modified car ferry.

Six times a year, Breakbulk hosts themed photo and video contests around a particular aspect of moving breakbulk and project cargo. The contests are open to all industry participants. Winners are selected by visitors to the website, so all participating companies are encouraged to get out the vote among their employees and friends. The winning entries can be viewed online at http://www.breakbulk.com/into-the-wild-standings/.

“The project cargo in this photo was an adventure and another example of our passion for excellence,” said Bahadir Erdil, Global Projects Director for Logistics Plus. “We drove through the heavy snow until the nearest shipyard to find an available ferry. There was no available barges on those dates so, as a solution, we found a car carrier ferry and cut some parts off the ferry to create a safe loading and discharging operation. We are thankful to Breakbulk and its constituency for recognizing our photo in this year’s contest.”

“The project cargo in this photo was an adventure and another example of our passion for excellence,” said Bahadir Erdil, Global Projects Director for Logistics Plus. “We drove through the heavy snow until the nearest shipyard to find an available ferry. There was no available barges on those dates so, as a solution, we found a car carrier ferry and cut some parts off the ferry to create a safe loading and discharging operation. We are thankful to Breakbulk and its constituency for recognizing our photo in this year’s contest.”

About Breakbulk Events & Media

Breakbulk Events host over 15,000 specialized logisticians annually in event formats that are focused on business development, logistics transactions, new cargo connections and strategy. The events are held around the world in locations known as project cargo hubs for the wider regions. Experts are handpicked to deliver compelling talks on timely issues and opportunities for those in the breakbulk and project cargo industry. Breakbulk hosts six events each year in Shanghai, China; Moscow, Russia; Antwerp, Belgium; Houston, U.S.; Kuala Lumpur, Malaysia and Abu Dhabi, UAE. But the connections and spread of knowledge don’t pause between events. Breakbulk also uses print and digital media to keep its colleagues informed year round. Learn more at www.breakbulk.com.

About Logistics Plus Inc.

Logistics Plus Inc. provides freight transportation, warehousing, global logistics, and supply chain management solutions through a worldwide network of talented and caring professionals. Founded in Erie, PA by local entrepreneur, Jim Berlin, 20 years ago, Logistics Plus is a fast-growing and award-winning transportation and logistics company. With a strong passion for excellence, its 400+ employees put the “Plus” in logistics by doing the big things properly, and the countless little things, that together ensure complete customer satisfaction and success.

The Logistics Plus® network includes offices located in Erie, PA; Alma, AR; Little Rock, AR; Los Angeles, CA; Riverside, CA; San Francisco, CA; Visalia, CA; Atlanta, GA; Chicago, IL; Detroit, MI; Kansas City, MO; Charlotte, NC; Lexington, NC; Buffalo, NY; Cleveland, OH; Charleston, SC; Greenville, SC; Nashville, TN; Dallas, TX; Fort Worth, TX; Houston, TX; Laredo, TX; Madison, WI; Bahrain; Belgium; Canada; Chile; China; Colombia; Egypt; France; Germany; India; Indonesia; Kazakhstan; Kenya; Libya; Mexico; Poland; Saudi Arabia; South Sudan; Turkey; UAE; and Uganda; with additional agents around the world. For more information, visit www.logisticsplus.com or follow @LogisticsPlus on Twitter.

###

Media Contact:

Scott G. Frederick

Vice President, Marketing

Logistics Plus Inc.

(814) 240-6881

scott.frederick@logisticsplus.com

Click image below to download the Logistics Plus logo:

by logisticsplus | Apr 25, 2017 | News

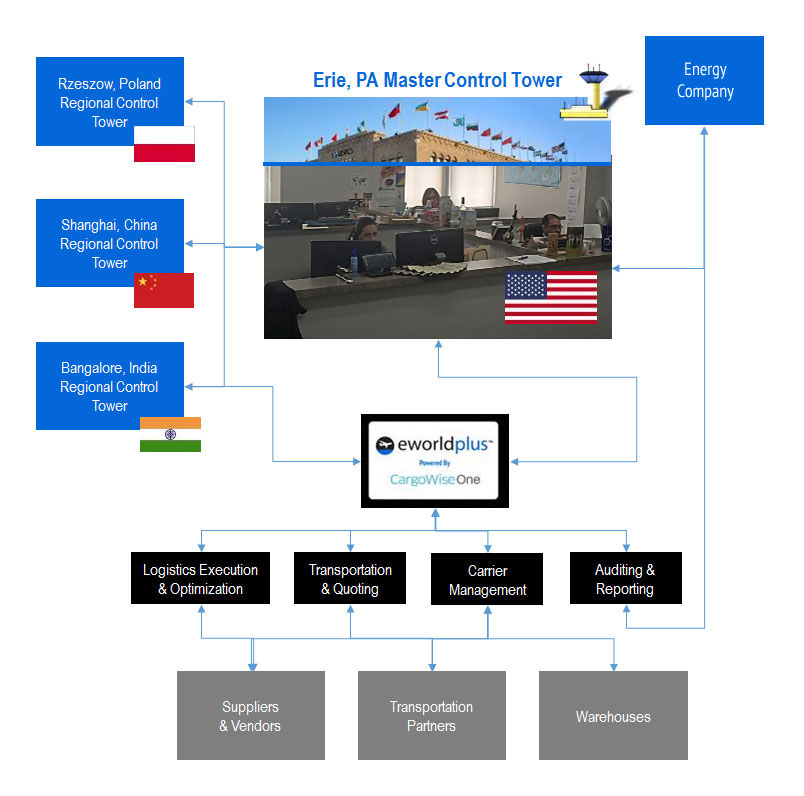

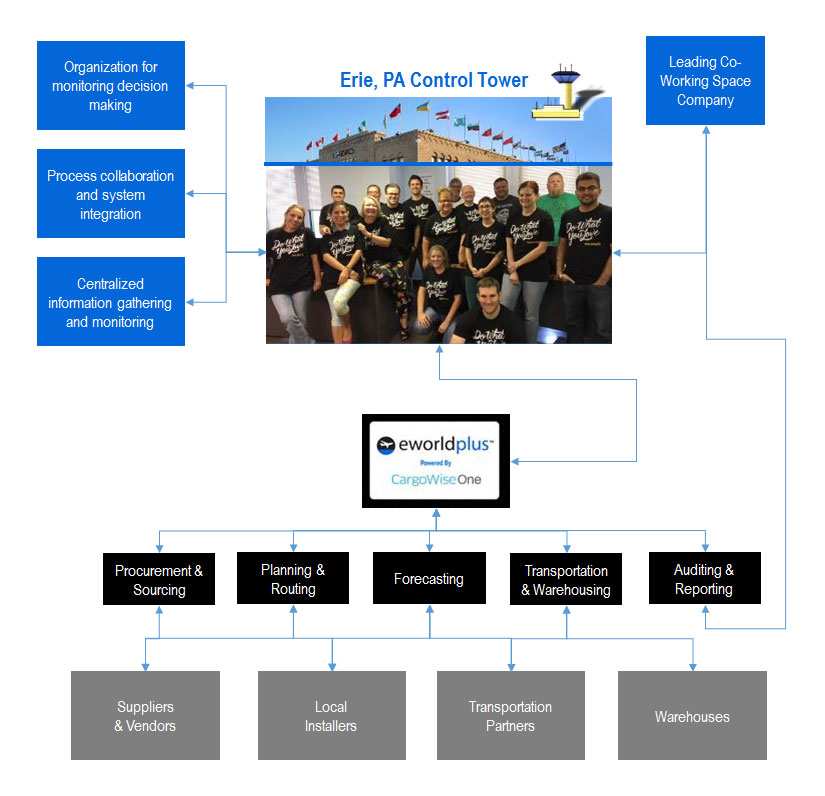

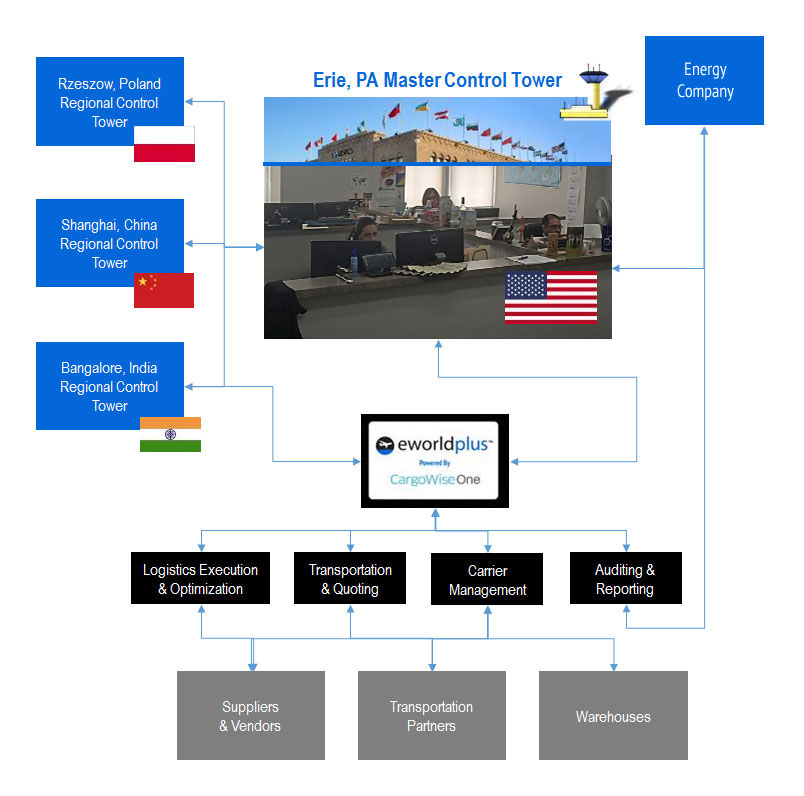

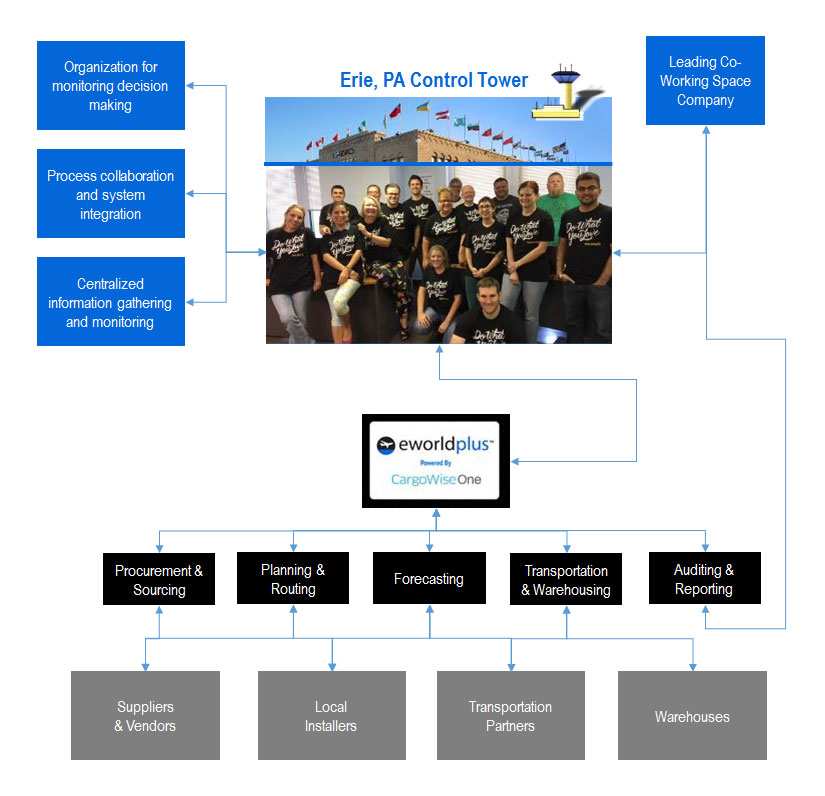

Global Supply Chain Control Towers are gaining interest among organizations that need greater visibility and control within their increasingly sophisticated supply chains. In a recent Capgemini Consulting report, a supply chain control tower is defined as a central hub with the required technology, organization and processes to capture and use supply chain data to provide enhanced visibility for short- and long-term decision making that is aligned with strategic objectives.

Global Supply Chain Control Towers are gaining interest among organizations that need greater visibility and control within their increasingly sophisticated supply chains. In a recent Capgemini Consulting report, a supply chain control tower is defined as a central hub with the required technology, organization and processes to capture and use supply chain data to provide enhanced visibility for short- and long-term decision making that is aligned with strategic objectives.

Supply chain towers are often an important component to 4PL supply chain solutions as companies realize that mastery of their supply chain must become a core competency to remain competitive. Although visibility within the supply chain is often a significant driver, the supply chain control tower must go beyond visibility to provide integrated transportation and logistics solutions and global trade compliance services. These services must be configured to support the needs of business units and the key fulfillment attributes of a product-line.

The value of having one global supply chain system and standardized processes gives companies the flexibility to plug in new transportation and logistics providers as needs change, or quickly assimilate new businesses. The control tower reduces the risk of getting locked into using an external provider’s system, and changes the balance of power. Control tower managers have the visibility and data-driven analysis of service levels to objectively manage each provider. Similarly, new businesses and product-lines can be plugged in with standard interfaces and highly configurable processes.

Logistics Plus has significant experience creating and managing global supply chain towers for a number of clients. We take a very customized, yet dedicated approach to configuring and integrating the control tower into each client’s supply chain. The two illustrations shown below are examples of control towers we have implemented for two very different companies (click to enlarge). One is a global energy company, and the other is a leading co-working space provider. As shown in the examples, the first company’s supply chain required multiple regional control towers to ensure visibility and control of logistics across multiple regions. In contrast, the second company required one primary, centrally-located control tower to oversee everything from procurement to warehousing to final deliveries.

If you’re looking for greater visibility and control within your supply chain, with an experienced 4PL partner that uses a very customized and dedicated approach, please contact us. We’d love to review your business challenge and discuss whether a global supply chain tower might be a good fit for your company.

by logisticsplus | Apr 24, 2017 | News

Our project cargo portfolio continues to grow as the Logistics Plus Project Cargo Team is keeping busy all around the world. Here are some recent cargo projects handled by our global team of logistics professionals:

Our project cargo portfolio continues to grow as the Logistics Plus Project Cargo Team is keeping busy all around the world. Here are some recent cargo projects handled by our global team of logistics professionals:

- Load a dismantled ship unloader from a barge in Taicang, China for transport to Grain Terminal in Haifa, Israel (normally only grain can be loaded/unloaded here, but we acquired permission under special permit from Port of Haifa).

- Pick up 84.5 metric ton heavy gas turbine from storage area in Antwerp, Belgium; load to barge, shift to outgoing terminal, and load on container vessel for breakbulk shipment by floating crane; final delivery to China.

- Pick up 94 metric ton heavy gas turbine from storage area in Antwerp, Belgium; shift to Rotterdam and load on container vessel for breakbulk shipment to Shanghai, China.

- Pick up two (2) oversized skids in Zaventem, Belgium and truck them all the way to Skogn, Norway.

- Receive damaged FGSS (fuel gas supply system) skid from Shanghai, China, and truck to Jiaxing factory for repairs. Upon completion of repairs, pick up at factory and truck back to Shanghai; ship to Imabari, Japan shipyard.

- Collect various components for re-liquefaction system from various suppliers; export to Shanghai; re-import and deliver to Hudong, China shipyard.

- Ship two moonpool hatches and components from Rotterdam, Netherlands to Suape, Brazil.

- Pick up three (3) windmill blades each 67 meters in length in Jiangyin, China; bring them to port and ship to Eemshaven, Netherlands.

- Pick up six (6) windmill blades each 50 meters in length in Tianjin, China; bring them to port and ship to Eemshaven, Netherlands.

- Ship 32 brewery system tanks and supporting legs from Antwerp, Belgium to Namibe, Angola.

The animated image below contains photographs from the projects described above.

Need help with your big, bad or ugly project cargo? Let us know!

by logisticsplus | Apr 21, 2017 | News

Check out these beautiful photographs provided by the Logistics Plus (LP) Project Cargo Team. These photos are from yet another successful project cargo movement coordinated jointly by the LP Turkey and LP Belgium offices. For this project, Logistics Plus safely loaded a 24.2m X 5.70m X 6.00m 105-ton cryogenic gas tank for transit from Turkey to Norway. Tune back in soon: We’ll be sharing a video of the final delivery too!

Check out these beautiful photographs provided by the Logistics Plus (LP) Project Cargo Team. These photos are from yet another successful project cargo movement coordinated jointly by the LP Turkey and LP Belgium offices. For this project, Logistics Plus safely loaded a 24.2m X 5.70m X 6.00m 105-ton cryogenic gas tank for transit from Turkey to Norway. Tune back in soon: We’ll be sharing a video of the final delivery too!

![]() Here is another cool cargo project involving the Logistics Plus Belgium team through our partnership with Carl Polzin.

Here is another cool cargo project involving the Logistics Plus Belgium team through our partnership with Carl Polzin.